Just when you thought the Seiko Watch Corporation had done it all, they go and reveal their latest innovation: the T0 Constant Force Tourbillon. This remarkable concept marks the world’s first movement with a fully integrated constant force and tourbillon on the same axis which seeks to power a mechanical watch with the highest accuracy possible.

Seiko have already launched two entirely new calibres this year, the Spring Drive 9RA5 and the Hi Beat 9SA5. Both movements showed significant change in the performance, power and versatility over their previous counterparts, with the Hi Beat 9SA5 in particular, causing quite a stir with its new escapement. It seems that alongside the development of these new calibres, Grand Seiko designers have been working on the new T0 – pronounce T Zero – constant force concept. As well as becoming the world’s first fully integrated constant force tourbillon, the calibre will be the first watch from Grand Seiko to incorporate the constant force device known as the remontoire.

What inspired the Grand Seiko T0 Constant Force Tourbillon Concept?

Since it’s release, the Seiko Spring Drive has won the hearts of watch enthusiasts and collectors around the world for its immaculate construction and innovative use of components. It was a desire to evolve the seemingly outdated mechanism of mechanical movements that instigated the Spring Drive to life, as it takes the accuracy of a quartz movement but remains powered by a mainspring. It is the same desire to update and advance the little-changed tourbillon movement that has spurred the creation of the new T0 Constant Force Tourbillon concept.

Thanks to hundreds of years of technological developments, mechanical watches have advanced in leaps and bounds since they were first invented, now providing better power reserves, precision and complications. However, one issue that remains is the mainspring that powers mechanical watches, an element that has changed very little. For those unfamiliar with the mainspring, it is a component within a mechanical movement that is essentially the main energy source of the watch. When it is wound, by either winding the crown or the oscillating rotor, it gains power (or torque) and loses power as it unwinds. Similarly, to how clockwork toys move energetically at first and move less as time passes.

Despite many attempts, the accuracy of a mechanical watch is always slightly lessened due to a variety of factors surrounding the mainspring unwinding. Seiko have managed to remedy some of these issues in several of their complex calibres, including the Grand Seiko 9SA5 which has a longer power reserve of 80 hours and a unique shaped hairspring, so it is able to maintain its accuracy for longer. However, as sticklers for perfection, Seiko intend to engineer a movement with a mainspring that remains the same whether fully wound or almost unwound.

For as long as spring-powered mechanical watches have been invented, manufacturers have been trying to ensure the steadiness of the torque to ensure the accuracy of the watch is higher. One solution that has proved successful is a fusee, a chain puller that makes the barrel pull a cone-shaped pulley with a chain. This means the fusee can produce stable torque if it is applied correctly. However, despite being used in marine chronometers, it has become difficult to mount a fusee in smaller timekeeping tools like pocket and wrist watches. Because of this, attention was drawn to something called a constant-force mechanism.

What is a Constant Force Mechanism?

As explained, when a watch is fully wound, the mainspring generates its maximum torque and as the tension decreases so does the oscillations and consequently its accuracy. So, for the balance oscillations to remain even at all times, the power transmitted through the wheel train and escapement must likewise be constant. A constant force mechanism works around these issues and preserves power in a small spring called a constant force spring. Unlike a mainspring, it uses the repulsive power of the small spring to power a pendulum or a balance. The mechanism is often compared to an impounding dam and is fantastic method for stabilising the torque.

Smaller in size and engineered from fewer components in comparison to a fusee, constant force mechanisms can be easier equipped within portable pocket watches and wrist watches. However due to difficultly in design and manufacturing, constant force mechanisms are still difficult to equip in a movement and only a few mechanical watches in history have been designed using then. It is also extremely difficult to engineer a constant-force mechanism for commercial use. For a long time, it seemed an almost impossible dream of watchmakers to harness the brilliance of a constant force mechanism. However, this dream appears to have become a reality with the announcement of the Grand Seiko T0 Constant Force Tourbillon concept.

How does the Grand Seiko T0 Constant Force Tourbillon work?

As its name suggests, the Grand Seiko T0 Constant Force Tourbillon contains a mechanism that combines a tourbillon with a constant force mechanism. The idea was first conceived in 2012 when Seiko movement designer and watchmaker Takuma Kawauchiya decided to seek the possibility of creating an ultra-high precision watch using the years of technology and experience Seiko had gained since its founding.

When constant force is placed close to a mainspring, it is easier to control its unwinding power. However, this also means efficiency is lower and the toque is uneven because it is further away from the balance. On the other hand, when the constant force mechanism is closer to the balance, it is able to deliver energy stably but the torque has to be controlled to a very small amount as it comes closer to the balance wheel, making it difficult to keep the stability. Therefore, Kawauchiya aimed to create a stable system while placing the constant force mechanism as close to the balance as possible.

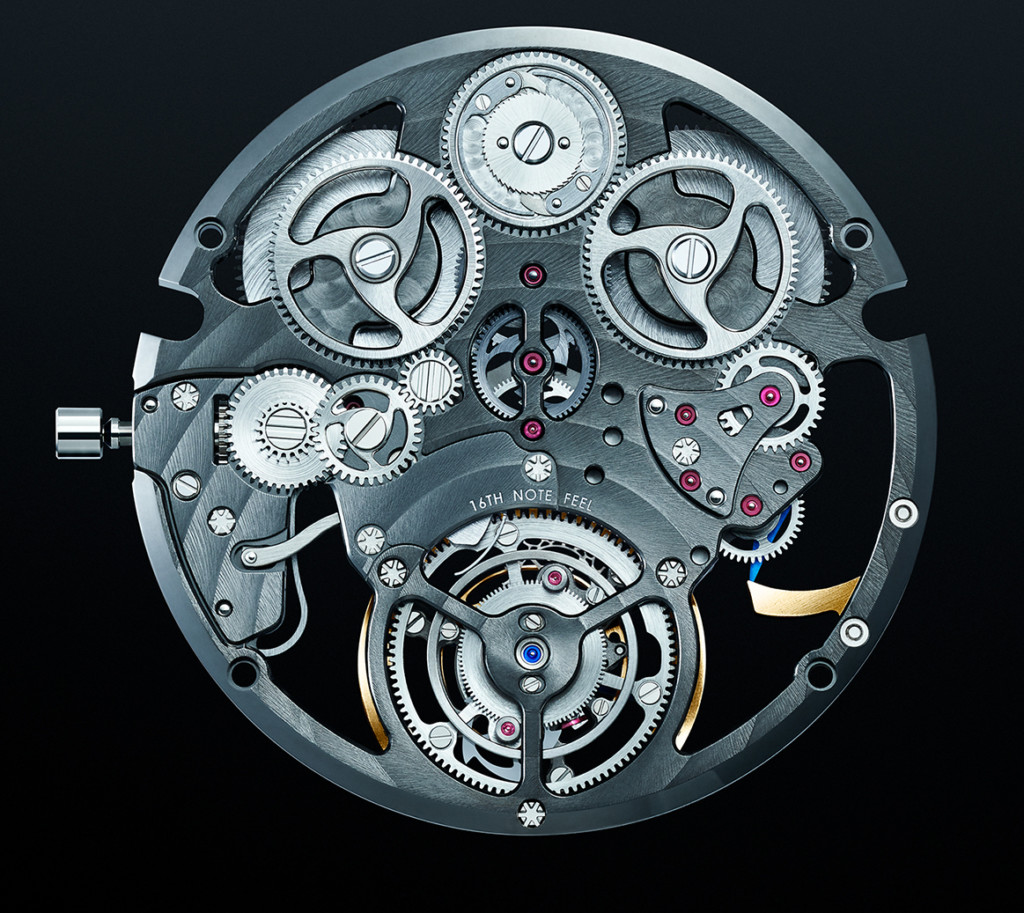

Kawauchiya decided to mount the constant force mechanism under a tourbillon, since the impact of gravity could be reduced this way. In most cases, a tourbillon has a unit called a carriage which combines a balance and an escape mountain on the fourth wheel that rotates once per minute. When a constant force is added, it is also normally placed away from the carriage. However, the Grand Seiko T0 Constant Force Tourbillon stores torque from a gear coaxially arranged with the carriage in a constant force spring, and the energy of the unwinding spring is used for rotating the carriage including the balance in it.

Several improvements were made to the concept to increase the torque and reduce resistance, one of which included placing twin barrels with two springs parallel to each other. This allowed the torque to be doubled and as a result marked the Grand Seiko T0 as the first movement in Seiko’s history to have two barrels placed parallel. Resistance was reduced by treating the centre and third wheels with a special coating to reduce friction and to accommodate the greater torque generated by the twin barrels. Since constant force stores the power of a mainspring and releases it in constant intervals, a stop wheel was also required to give high durability and low friction resistance. Kawauchiya applied a precise ceramic gear for the stop wheel, whose processing was precise to a micron level. As a result, T0 can operate with certainty every second without the wear of the stop wheel.

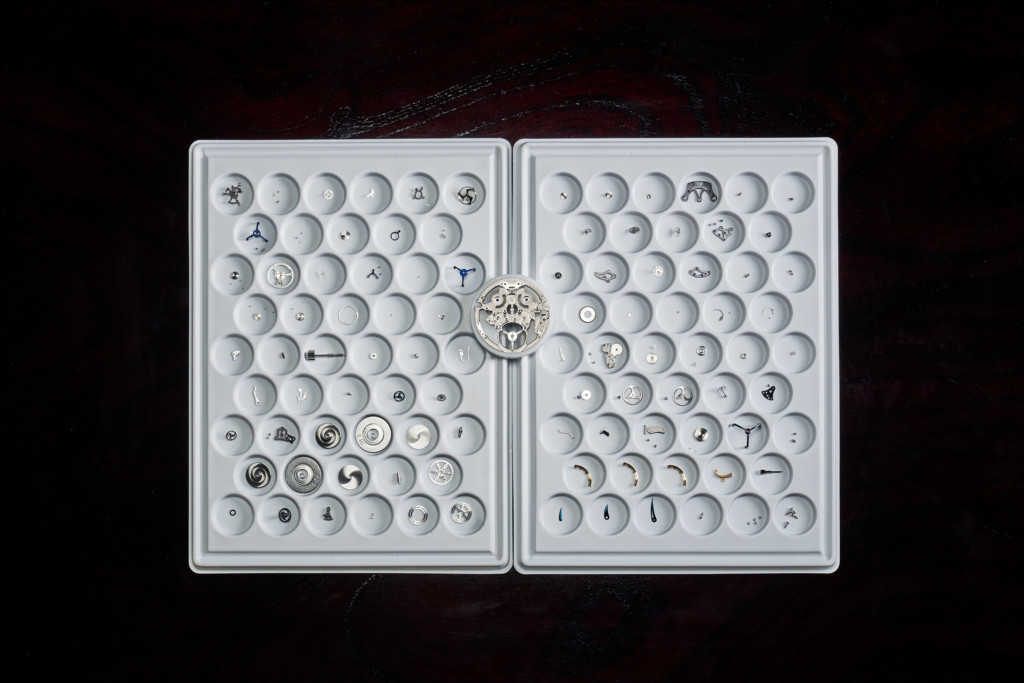

Similarly, to the Seiko Hi Beat movements, Takuma Kawauchiya machined many of the components within the Grand Seiko T0 Constant Force Tourbillon using Micro Electro Mechanical Systems (MEMS), a forming technique used for manufacturing semiconductors. This technology was originally utilised in Grand Seiko’s pallet fork and escapement wheel, but for the first time the technology is applied to almost all the gears. It works using metal films layered like plating to materialize a perfect gear tooth shape with precision measuring in microns.

Key components of the T0 such as the mainspring, wheel trains, escapement, balance, setting lever and yoke are all largely based on those of the Caliber 9S65, a tried and tested movement. Needless to say, improvements have been made to achieve a much higher precision. One of these is the use of a free-sprung balance without a regulator so that the gaining and losing of time through the inertia of the balance could be without changing the length of a hairspring. This also means it gains a higher shock resistance and maintains more stable precision for longer hours.

Another fantastic feature of the movement is its high frequency of 28,800 vibrations per hour – a feat when compared to the standard 21,600vph in most modern tourbillon wrist watches. It is also characterised by its 16th note ticking sound accompanied by the impact sound of a constant-force every second. It takes extremely high processing precision to ensure exact one-second periods for the release of torque by constant force and Kawauchiya wanted to make this procession precision perceivable as sound. The T0 achieves the perfect 16th note ticking sound with a ceramic stop wheel processed in precision at a micron level and the mechanism for finely regulating the timing of action. As expected, the historical value of the T0 technology is further raised with all the main plate and bridges hand finished by craftsman and women, a process that takes more than 3 months.

The Grand Seiko T0 Constant Force Tourbillon is without a doubt a true milestone not only for the Seiko brand but for the entirety of the watchmaking industry. It’s accuracy, construction and overall technological value proves once again that this Japanese watch manufacturer will never stop pursuing the best in accuracy which only gets us even more excited for the future of Grand Seiko watches. Keep your eyes peeled on the Horologii website for more news on this innovation and for the first Grand Seiko T0 watch to be unveiled.